What is Teflon coating moulds?

Mold Teflonizing" refers to the process of applying Teflon® or another brand of non-stick coating to the surface of molds. This treatment involves covering the mold surfaces with a specialized coating that prevents materials from sticking. Also thereby facilitating easier release of molded products and improving the efficiency and longevity of the molds. The application of such non-stick coatings can significantly enhance the performance and durability of molds used in various manufacturing processes.

Teflon coating moulds. Can any type of mould be Teflonized?

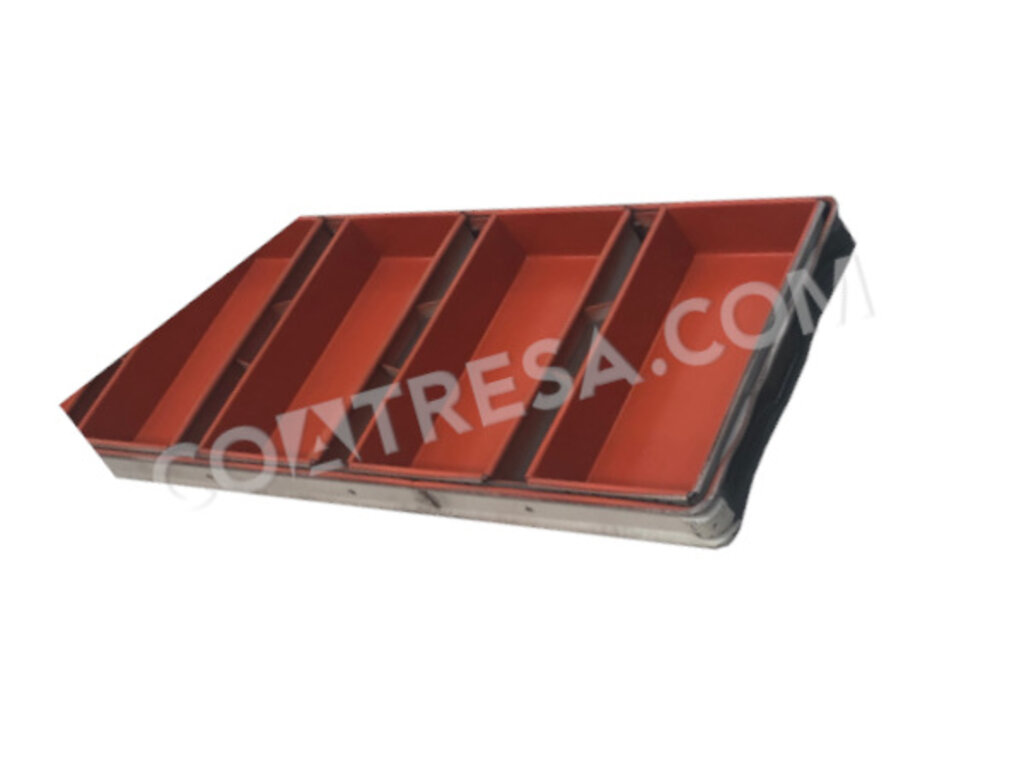

Teflon® molds are suitable for both the food and industrial sectors. Therefore, for the optimum performance of a mold, it is necessary that the material can flow and release easily, and for this, we can apply various types of technical non-stick coatings, which will avoid the use of release agents, and help to achieve a better result and better performance, without the need to stop the process to apply products such as oils or greases.

What is our objective?

At Coatresa Group, we study and recommend the appropriate Teflon coating moulds for each type of production, to provide the most appropriate non-stick coating for maximum durability and for the best performance of the products. In addition, we offer a complete service to industrial bakers for the construction with customized design, repair and maintenance of molds and trays for products such as sliced bread, baguettes, hamburger and hot dog buns, croissants and pastries.

If you need more information, do not hesitate to contact us!