Coatings for the packaging sector

Packaging is an essential part of industry, and may sometimes weigh more than the product itself. For this reason, COATRESA provides solutions to optimise the production of these products and contribute to the success of end product suppliers. Through the application of fluorinated products with high thermal resistance and non-stick properties such as FEP, PTFE or PFA we can help you cut costs in producing thermoformed plates, hoppers and vacuum hoods, welding lips and sonotrodes, blades, chains, bands, ramps, rails, sealing plates and thermosealing or welding appliances.

Depending on the part, the client requires specific characteristics for its optimum operation:

Thermoforming requires high thermal and abrasion resistance which is necessary to process these products, such as PE, PU, rubber, etc.

Main benefits of coatings for the packaging sector

- Reduction in production times

- Improved thermosealing quality

- Optimisation of packaging sealing

- Elimination of product loss due to adherence

- Less time needed for cleaning thanks to the non-stick surfaces

- Less maintenance due to stoppages or having to change parts with residue

- Improved sliding of parts during the production process

- Higher productivity of the machine due to less resistance to friction

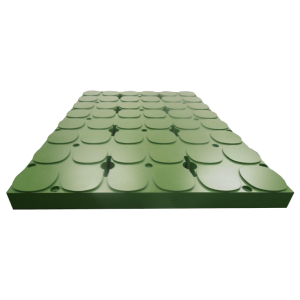

Some of our work in the packaging sector

All non stick coatings for this sector used by consumers are certified for contact with food based on current legislation (FDA 21 CFR 175.300, Regulation (EC) 1935/2004 and Regulation (EU) 10/2011)