Coatings for food processing machinery

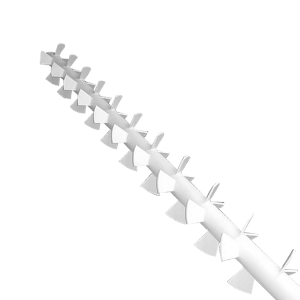

The food industry requires stopping times to be as short as possible, to optimise production processes. It is important for traces of food not to build up during the process and to avoid errors in weighing and filling due to excess product and so the machinery must have high non-stick properties and permit the easy passage of the foods. Each production process is unique. Our R&D department analyses each need in depth and our coatings are backed by an exhaustive study that helps us offer the best coating for each need. Some of the items that benefit from our treatments are bread dough hoppers, rotors, kneading machines, tanks, stirrers, injection nozzles, rollers, blades, worm shafts, conveyor belts, scales or dosing equipment.

All our coatings are non-stick, resistant to high temperatures and suitable for contact with food based on current standards (FDA 21 CFR 175.300, Regulation (EC) 1935/2004 and Regulation (EU) 10/2011). Our know-how and experience in the sector allows us to detect the best solution and we apply fluorinated products such as Teflon with a PTFE, PFA or FEP base, which have the required properties for the production processes of each client.

Main benefits of coatings for food processing machinery

- Reduction in cycle times

- Elimination of product loss due to adherence

- Optimisation of transport / dosing of raw materials

- Easy to clean

- Homogenisation of the finished product quality

- Increase in the useful life of components exposed to corrosion

Some of our work in the food machinery sector

Our high capacity facilities can process items ranging from small parts by means of completely robotised, controlled applications, to very large parts in which the coatings are applied by highly qualified staff.